- Tel:0086-0595-83993333

- cel:0086-13506902333

- E-mail:admin@jqfibre.com

- add:Longshi Road, Fashion Apparel Industrial Park, Longhu Town, Jinjiang City, Fujian

What is a polypropylene yarn? Polypropylene yarn raw material; introduction to the gauze, let us start from its biggest advantage. The biggest advantage is that the texture is light, and its density is only 0.91 g / cm3 is common in common chemical fibers, so the same weight of polypropylene can be higher than the higher coverage area obtained by other fibers. The strength of strong polypropylene is high, the strength is large, the initial modulus is high, and the elasticity is excellent. Therefore, the polypropylene wear resistance; in addition, the moisture of polypropylene is basically equal to the strength, so it is the ideal material for making fishnet, cable, and the moisture and dyeing properties are well warm; almost unheat, but the core suction ability is very strong. Moisture wicking is obvious; the hygroscopicity of polypropylene is small, almost unheathered, and the roll ratio under normal atmosphere is close to zero. In addition, polypropylene insulation is good, but static electricity is easily generated. Since the thermal conductivity of polypropylene is small, the strength is good; the strength of high polypropylene elastic wire is second only to nylon, but the price is only a nylon 1/3; the fabric size is stable, the wear-resistant elasticity is good, chemical stability is good.

The chemical molecules of the polypropylene yarn are also very different, and it is made of polypropylene fibers. Polypropylene has good heat resistance, and the article can be sterilized at a temperature of 100 ° C, which is not deformable at 150 ° C under conditions without external force. The embrittlement temperature is -35 ° C, which occurs below -35 ° C, and cold resistance is not as good as polyethylene. The report value of the polypropylene glass transition has a 18qc, 0qc, 5 ° C, etc., which is also due to the use of different samples, wherein the crystalline phase is different from the amorphous phase, so that the amorphous portion is different in the molecular chain. Cause. The melting temperature of the polypropylene is increased by about 40% by 40%, about 164, 170 ° C, 100%, and the like, and 100%. The chemical stability of the polypropylene is very good, and in addition to the concentrated sulfuric acid, concentrated nitric acid erosion, it is more stable to other various chemical reagents, but the low molecular weight of aliphatic hydrocarbon, aromatic hydrocarbon, etc. can soften polypropylene. Swelling, and its chemical stability increases with the increase in the crystallinity, so polypropylene is suitable for the production of various chemical pipes and fittings, and the anti-corrosion effect is good. It is because there are so many good advantages, and the effect of polypropylene yarn is more and more, the market is getting bigger and bigger.

Jinjiang Dako Textile Co., Ltd. was founded in 2011, where the "brand capital" Jinjiang, convenient transportation, 7 km from Jinjiang International Airport. The company is now covered by about 30 mu. The building area is about 20000m2. It is a professional company that is engaged in R & D, production and sales of polypropylene filaments.

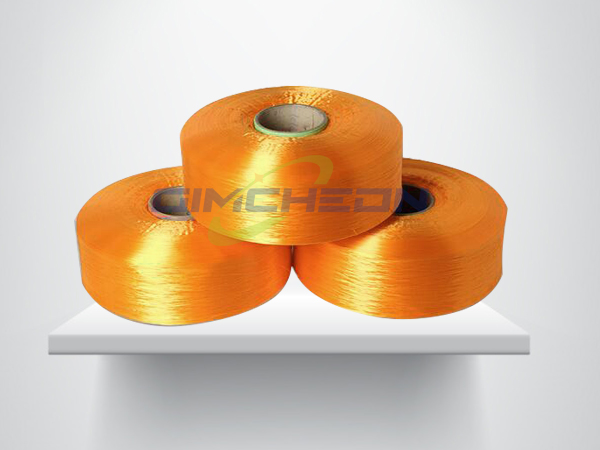

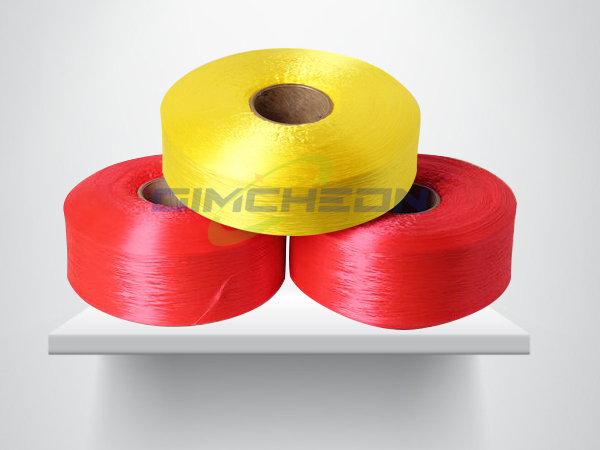

Our company has 20 polypropylene FDY production lines and several supporting equipment. It mainly produces 300D-1200D models of polypropylene regeneration yarn, polypropylene color yarn, and gratic gauze in polypropylene, with an annual output value of about 7,000 tons. Deco Textile adheres to the spirit of Jinjiang people to win, and has developed anti-aging, anti-ultraviolet, antibacterial, anti-static, anti-flame retardant functional fibers.

- How about clothes made of polypr

- The clothing industry is undergo

- Application field of polypropyle

- The dust of the US election has

- What are the broad uses of Texco

- Operation analysis of China's in

- From January to August this year

- Characteristics of polypropylene

- Application of polypropylene lig

- Textile industry scale and curre