- Tel:0086-0595-83993333

- cel:0086-13506902333

- E-mail:admin@jqfibre.com

- add:Longshi Road, Fashion Apparel Industrial Park, Longhu Town, Jinjiang City, Fujian

PP yarn is mainly used for webbing and rope mobile phone slings, shoelaces and backpack straps and other civilian webbings.

The maintenance work of PP yarn mainly includes the following three points:

The first method is to make the yarn soft by traditional mechanical methods, mainly through the soft yarn treatment, to destroy the glued film to show the softness. The disadvantage is that this method is easy to cause the PP yarn to pilling.

The second method is to increase the moisture regain of PP yarn, but pay attention to the range. If a large area is tested, the polypropylene yarn will become moldy, and the improvement in softness is not obvious. Or add a suitable softener during spinning, which can also improve the softness of the yarn.

Method 3 is similar to method 2. It softens the roving, also called roving oiling, softens the above-mentioned glued film, and then uses a softener to improve the softness of the PP yarn.

What is PP yarn, the advantages of PP yarn are introduced!

Belts woven from PP yarns with special properties can be used as car seat belts, safety belts for mountaineering, high-altitude and offshore operations, and air vehicle binding belts.

The performance characteristics of PP yarn are as follows:

Form: The longitudinal plane of polypropylene is straight and smooth, and the cross-section is circular;

Density: The biggest advantage of polypropylene is its light texture, and its density is only 0.91g/cm3, which is the lighter variety of common chemical fibers.

Jinjiang Deke Textile Co., Ltd. was founded in 2011. It is located in Jinjiang, the "brand capital", with convenient transportation, 7 kilometers away from Jinjiang International Airport. The company now covers an area of about 30 acres and a building area of about 20,000 square meters. It is an enterprise specializing in R&D, production and sales of polypropylene filament.

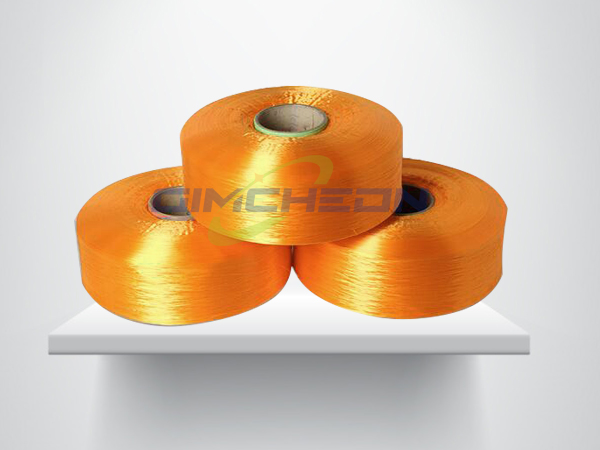

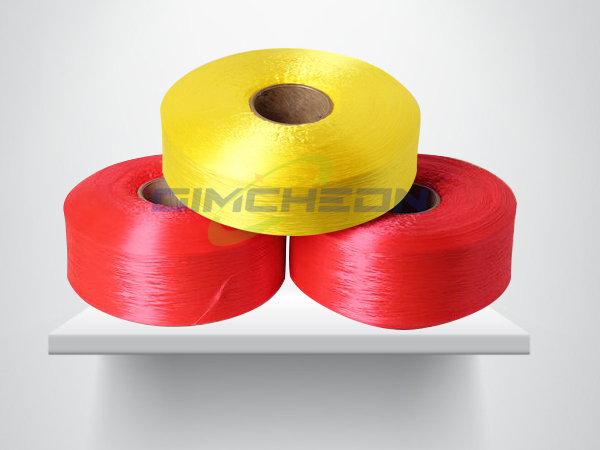

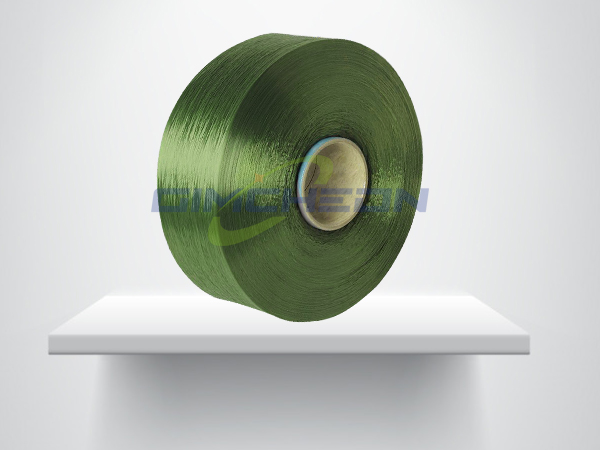

Our company has 20 polypropylene FDY production lines and a number of supporting equipment. Mainly produces 300D-1200D polypropylene recycled yarn, polypropylene dyed yarn, and polypropylene hollow yarn, with an annual output value of about 7,000 tons. Adhering to the spirit of Jinjiang people who love to work hard to win, Deke Textile has successively developed functional fibers with various colors of anti-aging, anti-ultraviolet, anti-bacterial, anti-static and anti-flame retardant.

- How about clothes made of polypr

- The clothing industry is undergo

- Application field of polypropyle

- The dust of the US election has

- What are the broad uses of Texco

- Operation analysis of China's in

- From January to August this year

- Characteristics of polypropylene

- Application of polypropylene lig

- Textile industry scale and curre